Page 46 - Vol_1_Chapter_III

P. 46

• Ability to produce complex shapes with minimal material waste.

• Parts with excellent dimensional accuracy and consistency.

However, deep drawing also has limitations:

• Certain shapes, such as those with sharp corners, may lead to material thinning or wrinkling.

• Material properties and thickness can influence the success of the process.

• Tool wear and maintenance may be factors, especially for larger production runs.

Overall, deep drawing is a versatile and widely used process for creating deep, hollow components from sheet metal, offering cost-effective

solutions for various industries and applications.

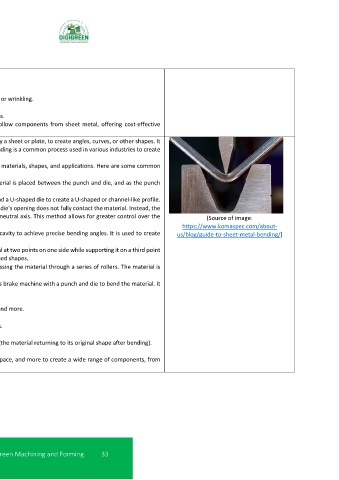

Bending The bending process is a manufacturing technique used to deform a material, typically a sheet or plate, to create angles, curves, or other shapes. It

involves applying force to the material, causing it to bend around a specified axis. Bending is a common process used in various industries to create

components with specific geometries.

There are several methods and types of bending processes, each suited for different materials, shapes, and applications. Here are some common

bending processes:

• V-Bending: In V-bending, the material is bent around a V-shaped die. The material is placed between the punch and die, and as the punch

descends, it forces the material to bend at the predetermined angle.

• U-Bending: Similar to V-bending, U-bending involves bending the material around a U-shaped die to create a U-shaped or channel-like profile.

• Air Bending: In air bending, the material is bent using a punch and a die, but the die's opening does not fully contact the material. Instead, the

material is bent by applying force without the die touching the material at its neutral axis. This method allows for greater control over the (Source of image:

bend angle and minimizes tool wear. https://www.komaspec.com/about-

• Bottoming or Coining: In this method, the material is fully forced into the die cavity to achieve precise bending angles. It is used to create us/blog/guide-to-sheet-metal-bending/)

accurate and repeatable bends.

• Three-Point Bending: Three-point bending involves applying force to the material at two points on one side while supporting it on a third point

on the opposite side. This method is commonly used for creating curved or arched shapes.

• Roll Bending: Roll bending is used to create cylindrical or conical shapes by passing the material through a series of rollers. The material is

gradually bent as it passes between the rollers.

• Press Brake Bending: Press brake bending is a versatile method that uses a press brake machine with a punch and die to bend the material. It

is commonly used for precision bending of sheets and plates.

Bending offers several advantages:

• It allows for the creation of various shapes, including angles, curves, channels, and more.

• Bending is suitable for both large and small production runs.

• It is a cost-effective method for producing components with specific geometries.

However, bending also has limitations:

• Certain materials and thicknesses may be difficult to bend without spring-back (the material returning to its original shape after bending).

• Sharp bends or tight radii can lead to cracking or material deformation.

Bending is used in industries such as metalworking, construction, automotive, aerospace, and more to create a wide range of components, from

brackets and chassis parts to architectural elements and decorative pieces.

Copyright © by DIGIGREEN All Rights Reserved Volume I – Chapter III: Digital and Green Machining and Forming 33