Page 44 - Vol_1_Chapter_III

P. 44

Extrusion is utilized in industries such as construction, automotive, aerospace, packaging, and more. Products created through extrusion include

pipes, tubes, rods, wires, window frames, plastic profiles, and various other structural components.

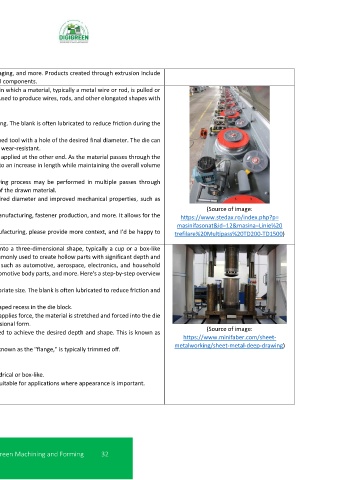

Drawing Drawing, in the context of manufacturing, usually refers to a metal forming process in which a material, typically a metal wire or rod, is pulled or

"drawn" through a die to reduce its diameter or thickness. This process is commonly used to produce wires, rods, and other elongated shapes with

precise dimensions and improved mechanical properties.

Here's a brief overview of the drawing process:

• Setup: A metal rod or wire, known as a "blank" or "billet," is prepared for drawing. The blank is often lubricated to reduce friction during the

drawing process.

• Drawing Die: The blank is inserted into a drawing die, which is a specially designed tool with a hole of the desired final diameter. The die can

be made from materials like carbide or diamond, which are extremely hard and wear-resistant.

• Drawing Process: The blank is pulled through the drawing die by a pulling force applied at the other end. As the material passes through the

die, its diameter is reduced, and it elongates. This reduction in diameter leads to an increase in length while maintaining the overall volume

of the material.

• Multiple Passes: Depending on the desired reduction in diameter, the drawing process may be performed in multiple passes through

progressively smaller dies. Each pass refines the dimensions and surface finish of the drawn material.

• Finished Product: The drawn material exits the last drawing die with the desired diameter and improved mechanical properties, such as

increased tensile strength and hardness due to the plastic deformation. (Source of image:

The drawing process is used in various industries, including wire production, cable manufacturing, fastener production, and more. It allows for the https://www.stedax.ro/index.php?p=

creation of precisely sized and dimensionally consistent products. masinifasonat&id=12&masina=Linie%20

If you had a different specific term or process in mind related to machining or manufacturing, please provide more context, and I'd be happy to trefilare%20Multipass%20TD200-TD1500)

provide further information.

Deep Drawing Deep drawing is a metal forming process used to transform a flat sheet of metal into a three-dimensional shape, typically a cup or a box-like

structure, by using a punch to force the material into a die cavity. This process is commonly used to create hollow parts with significant depth and

a consistent cross-sectional shape. Deep drawing is widely employed in industries such as automotive, aerospace, electronics, and household

appliances to manufacture various components, including cans, containers, sinks, automotive body parts, and more. Here's a step-by-step overview

of the deep drawing process:

• Blank Preparation: A flat sheet of metal, known as a "blank," is cut to the appropriate size. The blank is often lubricated to reduce friction and

facilitate the drawing process.

• Placing the Blank: The blank is placed over the die cavity, which is a concave-shaped recess in the die block.

• Drawing: A punch descends and contacts the centre of the blank. As the punch applies force, the material is stretched and forced into the die

cavity. The sidewalls of the die shape the material into the desired three-dimensional form.

• Redrawing (if needed): In some cases, multiple drawing stages may be required to achieve the desired depth and shape. This is known as (Source of image:

"redrawing." https://www.minifaber.com/sheet-

• Trimming: After the drawing process, excess material around the formed part, known as the "flange," is typically trimmed off. metalworking/sheet-metal-deep-drawing)

Key characteristics of deep drawing include:

• The depth of the drawn part is significantly greater than its diameter.

• The cross-sectional shape of the drawn part is typically consistent, such as cylindrical or box-like.

• The process produces parts with smooth and seamless surfaces, making them suitable for applications where appearance is important.

Advantages of deep drawing include:

• High production rates and efficient use of material.

Copyright © by DIGIGREEN All Rights Reserved Volume I – Chapter III: Digital and Green Machining and Forming 32